Page 20 - Demo

P. 20

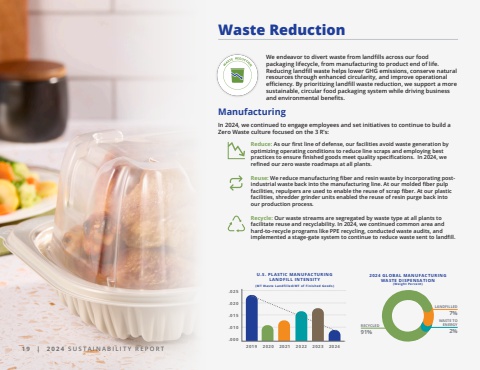

19 | 2024 SUSTAINABILITY REPORTWaste ReductionWe endeavor to divert waste from landfills across our food packaging lifecycle, from manufacturing to product end of life. Reducing landfill waste helps lower GHG emissions, conserve natural resources through enhanced circularity, and improve operational efficiency. By prioritizing landfill waste reduction, we support a more sustainable, circular food packaging system while driving business and environmental benefits. Manufacturing In 2024, we continued to engage employees and set initiatives to continue to build a Zero Waste culture focused on the 3 R%u2019s:Reduce: As our first line of defense, our facilities avoid waste generation by optimizing operating conditions to reduce line scraps and employing best practices to ensure finished goods meet quality specifications. In 2024, we refined our zero waste roadmaps at all plants. Reuse: We reduce manufacturing fiber and resin waste by incorporating postindustrial waste back into the manufacturing line. At our molded fiber pulp facilities, repulpers are used to enable the reuse of scrap fiber. At our plastic facilities, shredder grinder units enabled the reuse of resin purge back into our production process.Recycle: Our waste streams are segregated by waste type at all plants to facilitate reuse and recyclability. In 2024, we continued common area and hard-to-recycle programs like PPE recycling, conducted waste audits, and implemented a stage-gate system to continue to reduce waste sent to landfill.2024 GLOBAL MANUFACTURING WASTE DISPENSATION(Weight Percent)LANDFILLED7%WASTE TO ENERGY2%RECYCLED91%(MT Waste Landfilled/MT of Finished Goods)U.S. PLASTIC MANUFACTURING LANDFILL INTENSITY.000.025.020.010.0152019 2020 2021 2022 2023 2024 19 | 2024 SUSTAINABILITY REPORT