Page 26 - Demo

P. 26

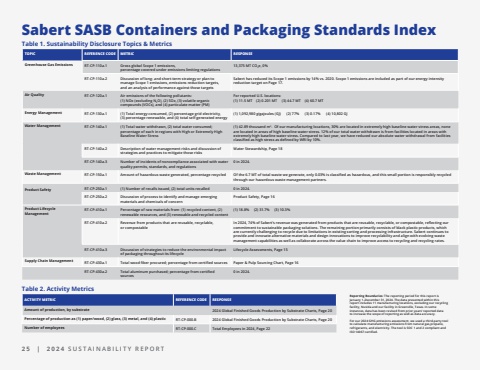

25 | 2024 SUSTAINABILITY REPORTSabert SASB Containers and Packaging Standards IndexTable 1. Sustainability Disclosure Topics & MetricsTable 2. Activity MetricsReporting Boundaries: The reporting period for this report is January 1%u2013December 31, 2024. The data presented within this report includes 11 manufacturing locations, excluding our recycling facility, Nuvida and our facility in Greenville, Texas. In some instances, data has been revised from prior years%u2019 reported data to increase the scope of reporting as well as data accuracy.For our 2024 GHG emissions assessment, we used a third-party tool to calculate manufacturing emissions from natural gas,propane, refrigerants, and electricity. The tool is SOC 1 and 2 compliant and ISO 14067 certified.ACTIVITY METRIC REFERENCE CODE RESPONSEAmount of production, by substrate RT-CP-000.A 2024 Global Finished Goods Production by Substrate Charts, Page 20Percentage of production as (1) paper/wood, (2) glass, (3) metal, and (4) plastic RT-CP-000.B 2024 Global Finished Goods Production by Substrate Charts, Page 20Number of employees RT-CP-000.C Total Employees in 2024, Page 22TOPIC REFERENCE CODE METRIC RESPONSEGreenhouse Gas Emissions RT-CP-110a.1 Gross global Scope 1 emissions,percentage covered under emissions limiting regulations13,375 MT CO2e, 0%RT-CP-110a.2 Discussion of long- and short-term strategy or plan to manage Scope 1 emissions, emissions reduction targets,and an analysis of performance against those targetsSabert has reduced its Scope 1 emissions by 14% vs. 2020. Scope 1 emissions are included as part of our energy intensity reduction target on Page 17.Air Quality RT-CP-120a.1 Air emissions of the following pollutants:(1) NOx (excluding N2O), (2) SOx, (3) volatile organic compounds (VOCs), and (4) particulate matter (PM)For reported U.S. locations:(1) 11.5 MT (2) 0.201 MT (3) 44.7 MT (4) 60.7 MTEnergy Management RT-CP-130a.1 (1) Total energy consumed, (2) percentage grid electricity,(3) percentage renewable, and (4) total self-generated energy(1) 1,092,980 gigajoules (GJ) (2) 77% (3) 0.17% (4) 10,802 GJWater Management RT-CP-140a.1 (1) Total water withdrawn, (2) total water consumed; percentage of each in regions with High or Extremely High Baseline Water Stress(1) 42.89 thousand m3. Of our manufacturing locations, 30% are located in extremely high baseline water stress areas, none are located in areas of high baseline water stress. 12% of our total water withdrawn is from facilities located in areas with extremely high baseline water stress. Compared to last year, we have reduced our absolute water withdrawal from facilities classified as high stress as defined by WRI by 10%.RT-CP-140a.2 Description of water management risks and discussion of strategies and practices to mitigate those risksWater Stewardship, Page 18RT-CP-140a.3 Number of incidents of noncompliance associated with water quality permits, standards, and regulations0 in 2024.Waste Management RT-CP-150a.1 Amount of hazardous waste generated, percentage recycled Of the 6.7 MT of total waste we generate, only 0.03% is classified as hazardous, and this small portion is responsibly recycled through our hazardous waste management partners. Product Safety RT-CP-250a.1 (1) Number of recalls issued, (2) total units recalled 0 in 2024.RT-CP-250a.2 Discussion of process to identify and manage emerging materials and chemicals of concernProduct Safety, Page 16Product Lifecycle Management RT-CP-410a.1 Percentage of raw materials from: (1) recycled content, (2) renewable resources, and (3) renewable and recycled content(1) 18.8% (2) 31.7% (3) 10.3%RT-CP-410a.2 Revenue from products that are reusable, recyclable, or compostableIn 2024, 74% of Sabert%u2019s revenue was generated from products that are reusable, recyclable, or compostable, reflecting our commitment to sustainable packaging solutions. The remaining portion primarily consists of black plastic products, which are currently challenging to recycle due to limitations in existing sorting and processing infrastructure. Sabert continues to provide and innovate alternative materials and design innovations to improve recyclability and align with evolving waste management capabilities as well as collaborate across the value chain to improve access to recycling and recycling rates.RT-CP-410a.3 Discussion of strategies to reduce the environmental impact of packaging throughout its lifecycle Lifecycle Assessments, Page 15Supply Chain Management RT-CP-430a.1 Total wood fiber procured; percentage from certified sources Paper & Pulp Sourcing Chart, Page 16RT-CP-430a.2 Total aluminum purchased; percentage from certified sources0 in 2024.